ELECTRICAL INTEGRITY MONITORING

FOR LONG-TERM ENVIRONMENTAL PROTECTION

Texplor’s MSS® Sealing Integrity Monitoring System permanently observes the tightness of sealing systems of all kinds. We add another safety level of protection where you can’t afford a leak.

Automatic

leak alarm

Early detection of leak areas to protect the stored resources and the environment

Fast installation

after liner construction

In most cases within a week, all cables are laid above the liner

Sensors & cables

certified for 100 years

No load limit, resistant in pH 1 – 14

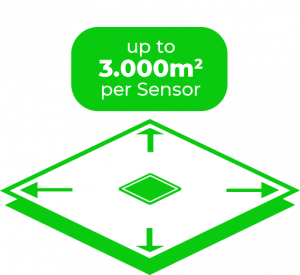

Sensors cover

large areas

Per sensor between 1.000 – 3.000 m2 of liner surface

Leak

localization

Detection of damaged areas enables fast & targeted repair works

Service &

maintenance

Regular remote support within the framework of a service contract

Our permanent monitoring technology and service is important for the long-term protection of the contained storage and the environment, the groundwater and the maintenance of water resources.

Whatever the application – if you have a critical need to ensure the integrity of the sealing system, our MSS® Sealing Integrity Monitoring System does the job.

24/7 INTEGRITY MONITORING

OF YOUR STORED RESOURCES

- All types of sealing systems.

- Extension of the service life of the sealing system. Makes further use possible.

- Works excellently under difficult conditions and complex industrial areas.

NEXT LEVEL OF QUALITY ASSURANCE AND RISK MANAGEMENT

WHAT SETS US APART

TEXPLOR developed a complete turnkey Sealing Integrity Monitoring System that provides the highest level of sealing tightness control and risk management from the start of your construction for future years of operation.

Our permanent monitoring system can help reduce the risk of environmental pollution, which is a deep concern to owners of landfills, mines, and industrial sites. It can also help protect against expensive solution loss in mining applications or help preserve fresh water resources.

Texplor is committed to its high-tech approach to smart leak localization, and applies it on every step of the whole procedure; from the first technical planning to the installation to the setting up of the system.

TECHNOLOGY IS THE KEY TO SYMBIOSIS BETWEEN INDUSTRY AND ENVIRONMENT

We are leaders in the field of permanent leak detection systems to detect leaks and avoid unnoticed damages.

Our contribution to people and the environment is a state-of-the-art permanent monitoring system that makes sealing systems of all kinds more secure by permanently confirming their tightness. This assurance means confirmed reliability of these systems so that people and the environment can be safe.

Our clients depend on us to deliver solutions that withstand virtually every threat imaginable while providing the best possible performance.

And we take that responsibility seriously.

RANGE OF APPLICATIONS

HOW IT WORKS

SMART LEAK LOCATION QUALITY CONTROL

The MSS® Sealing Integrity Monitoring System is a state-of-the-art electronic system for checking tightness, allowing any leakage problems in all types of sealing systems to be detected at an early stage.

Our permanent Monitoring System works by automatically measuring and evaluating the electrical fields above and below the sealing using Texplor’s MSS® CombiModules, Single Sensors or Cable Sensors.

The core of the system is the central computer unit that controls the measurement cycles, stores the data in a database and calculates automatically if an alarm situation occurs.

In the event of a leakage, an optical and/or acoustic signal is issued in the central computer unit and is forwarded to the client’s electronic surveillance system.

CERTIFIED AND RELIABLE

The sensors withstand pressures > 10 MPa and are resistant against liquids or materials with pH values 1-14.

By using low voltage the system can also be operated in explosion protected environments.

The MSS® Sealing Integrity Monitoring System works according to AS SIKB 6702 (Netherlands), and can identify leaks bigger than 1 mm² according to ASTM D7909/21a (USA).

- MSS® CombiModules: 100 years certified durability

- Production accord. DIN ISO 9001:2015, operation accord. AS SIKB 6702 (NL)

- Millimeter size leakage resolution (≥ 1 mm²)

TAILORED TO OUR CUSTUMER NEEDS

PLANNING & INSTALLATION OF OUR MONITORING SYSTEM

It all starts in the stage of planning. The systems are project specific and can be adapted to any situation or location.

Our technical team assesses the planned design of the basin or containment and plans the design of the MSS® Sealing Integrity Monitoring System specifically for each project to guarantee the best and cost-effective performance.

The installation of our systems takes place after installation of the liner or during its expansion in a short time. The MSS® CombiModules are embedded into the geomembrane by the geosynthetic installer. All cables are laid above the liner so no installation below the geomembrane is necessary. The system can be installed in new or existing facilities and can be expanded at any time.

The grid of the sensors is individually adapted and optimized to the local conditions. All electrical and monitoring components are mounted at site and easily accessible for service and maintenance.

Texplor sends a team of experts to the site for a proper commissioning of the system and for training of the operators.

Use our innovative technology & know how to thrive your projects

Contact us:

By sending this message you consent to your entered data (Name, e-mail address and message) being stored according to our privacy policy.